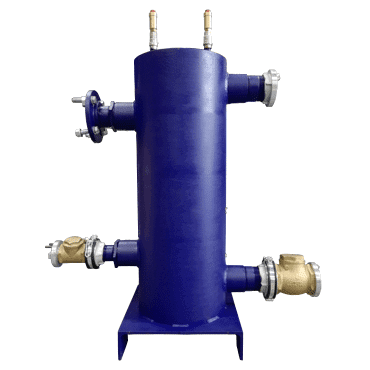

What is a low loss header?

The purpose of a low loss header is to enable hydraulic separation between the boiler & heating circuit. The low loss header helps to improve the performance & efficiency of the heating system. Furthermore, it helps regulate the system’s flow rate & pressure.

What is its purpose?

The heating system a boiler is directly connected to may have a variable flow rate. This is caused by Thermostatic Radiator Control Valves & system control valves. A variable flow rate could lead to the issue of struggling to maintain the minimum boiler flow rate. Therefore, a low loss header is of the utmost importance to help regulate the system’s flow rate.

How do they work?

A low loss header helps maintain a constant flow rate in the primary circuit through separating the two systems. A constant flow rate is provided for the primary circuit while the temperature fluctuates in the secondary circuit. Interaction between the two systems is therefore prevented & makes the primary circuit return temperature representative of the load on the system.

Factors which must be taken into consideration when installing a low loss header

Boilers

- Take into account the number of boilers which are installed on the primary circuit. Look at the circuit temperature differentials & the allowed minimum flow rates.

Pumps

- If the boiler does not already have an integral pump, additional pumps may be needed depending on the resistance flow rate of the boiler.