About Evaporative Cooling

Evaporative Cooling is an inexpensive & efficient way to cool warehouses & buildings during the summer heat. Uses for an evaporative cooling system vary from cooling data centres & schools to warehouses, factories & workshops. Although this may seem like a modern concept, evaporative cooling has been in use for centuries tracing its roots to the Ancient Egyptians who placed wet blankets on doorways in the hot sun as fresh air blew cool air in.

Types of Evaporative Cooling Systems

There are 3 main types of evaporative cooling systems – direct, indirect & hybrid.

Direct System

Direct evaporative coolers are used for space cooling. Air is taken from outside & passed over a damp surface to then be released back into the environment providing a cooling effect. The warm air evaporates the water on the wet surface changing its state from a liquid to a vapour. The evaporation process cools the hot air which has been passed through the unit.

It is important to note that if the air is too cool then the evaporative coolers will not work as it will not be hot enough for the evaporation process to take place. However, if the humidity is too high then the saturated air will not be able to absorb more water. Therefore, it is important to make sure that these air conditioning units are used in the right environment & conditions.

Direct evaporative coolers tend to be the most effective evaporative cooling system due to there being no heat transfer device. Each further step of heat transfer will reduce the effectiveness of the evaporative cooler.

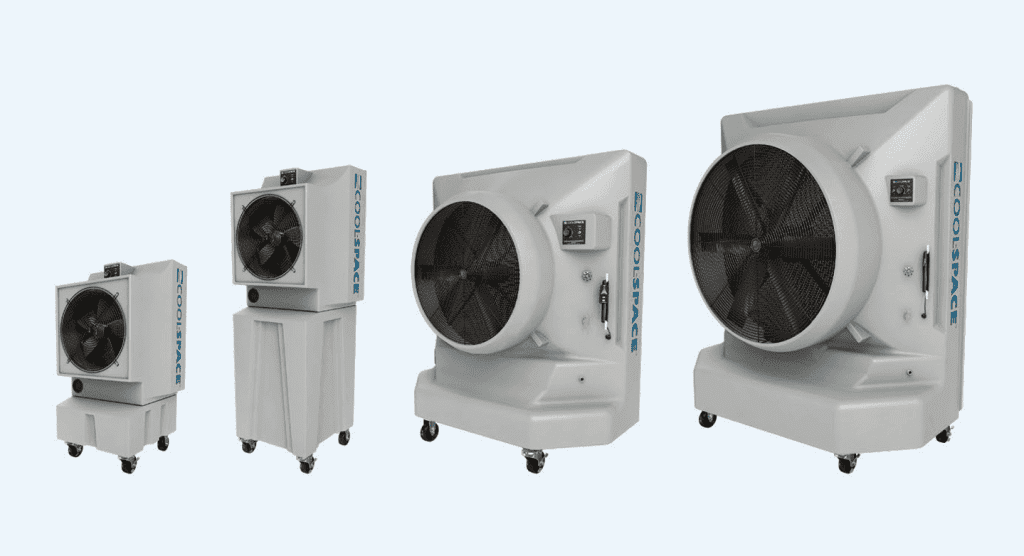

Cross Rental Services have a range of evaporative coolers suitable for a number of tasks from office cooling to industrial cooling.

Indirect System

An indirect evaporative cooling system makes use of a heat transfer component which uses a secondary air stream to produce cold water. This cold water goes through the heat transfer component to cool the primary air stream which is circulated through blowers.

Although a heat transfer device prevents a humidity increase, it is not as effective as using a direct system as previously mentioned. An advantage of using an indirect system is that it is able to recirculate air in the space if required.

Hybrid System

A hybrid system makes use of both direct & indirect evaporative coolers. Through this method some moisture is added to the air through the direct coolers, however, this is less than if direct evaporative coolers were solely used. The process works through an indirect system cooling the air for it be lowered even further by a direct cooling system.

Factors to take into consideration when cooling Industrial Spaces

- Cost – The least expensive method of evaporative cooling would be through using the direct coolers due to their low installation cost & upkeep. The most expensive would be a hybrid system.

- Spot Cooling – Direct evaporative coolers are most commonly used for spot cooling instead of large-volume cooling. A disadvantage of large volume cooling is that there is a high electrical energy cost required to run the fans & generate air movement.

- Humidity – It is important to keep in mind that evaporative cooling releases moisture into the atmosphere. Therefore, it is is not suitable for manufacturing processes in which the products made are susceptible to water such as working with powders.

- Water consumption – Remember to constantly monitor the water consumption of the evaporative coolers and fill up the water reservoirs if they reach a low level.