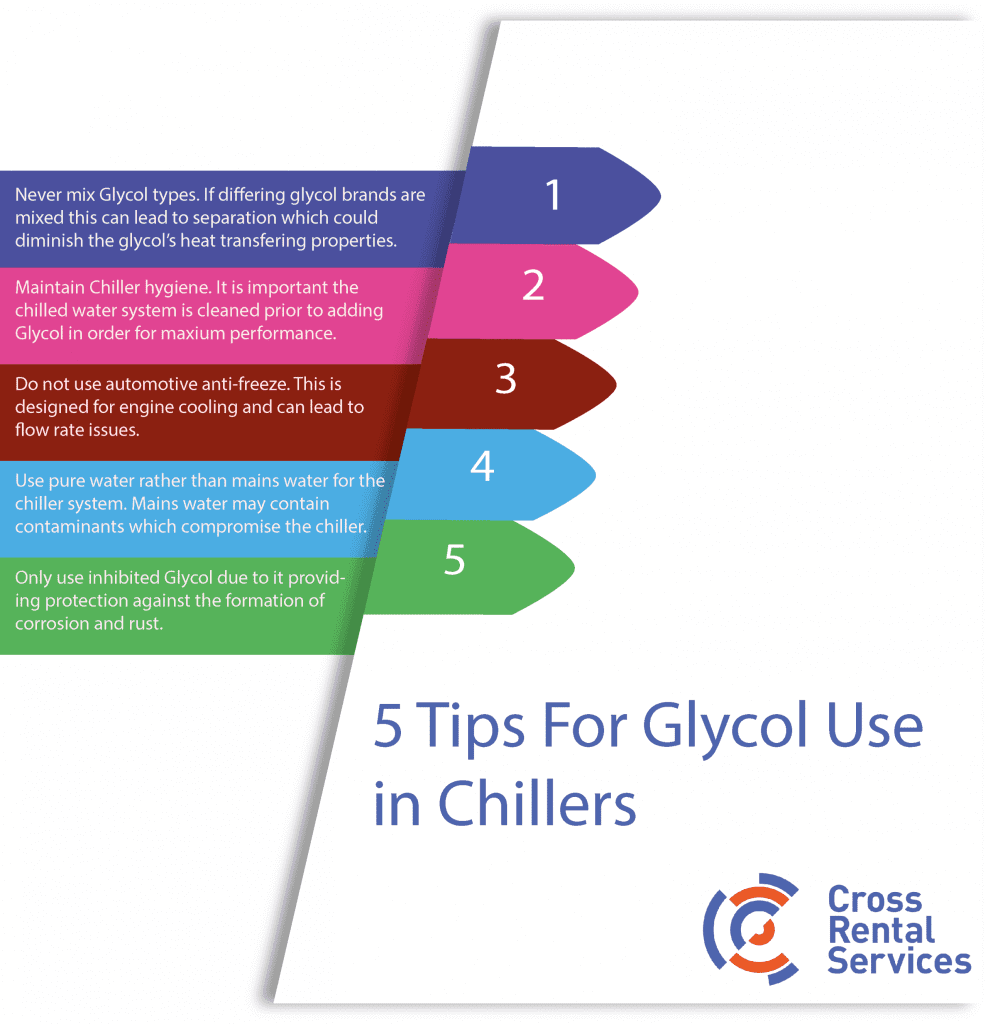

Never Mix Glycol Types

If different brands of Glycol are mixed then this can lead to problems such as separation. Separation can lead to a gel forming which will potentially block filters and strainers. Another potential issue which could arise from mixing different Glycol types is a deterioration in the heat transferring property of the Glycol.

Maintain Chiller Hygiene

Regularly check the filters and strainers before adding a new Glycol solution. It is important to ensure the chilled water system is cleaned before Glycol is added due to unhygienic conditions compromising the chiller’s ability to transfer heat.

Do Not Use Automotive Antifreeze

Automotive antifreeze is designed for engine cooling rather than industrial or process cooling, therefore when used in chillers for these applications, problems such as flow rate issues and reduced heat transfer will occur. This is due to automotive antifreeze products not having a base of Glycol with them instead having a base of glycerine or other alcohols.

Correct Water?

The majority of systems use mains “tap” water which can potentially damage chillers. The hardness and the number of microbiological contaminants in ordinary mains water differs from town to town, therefore we advise using a “pure” water to prevent the unpredictability caused from ordinary mains water. Pure water is a collective term for water that is distilled, de-ionised, de-mineralised or RO water.

Inhibited Glycol Only

Uninhibited Glycol can be even more corrosive than standard mains water, therefore we advise to only use inhibited Glycol. Modern Glycol contains inhibitors to help provide protection against the formation of scale, corrosion and rust.