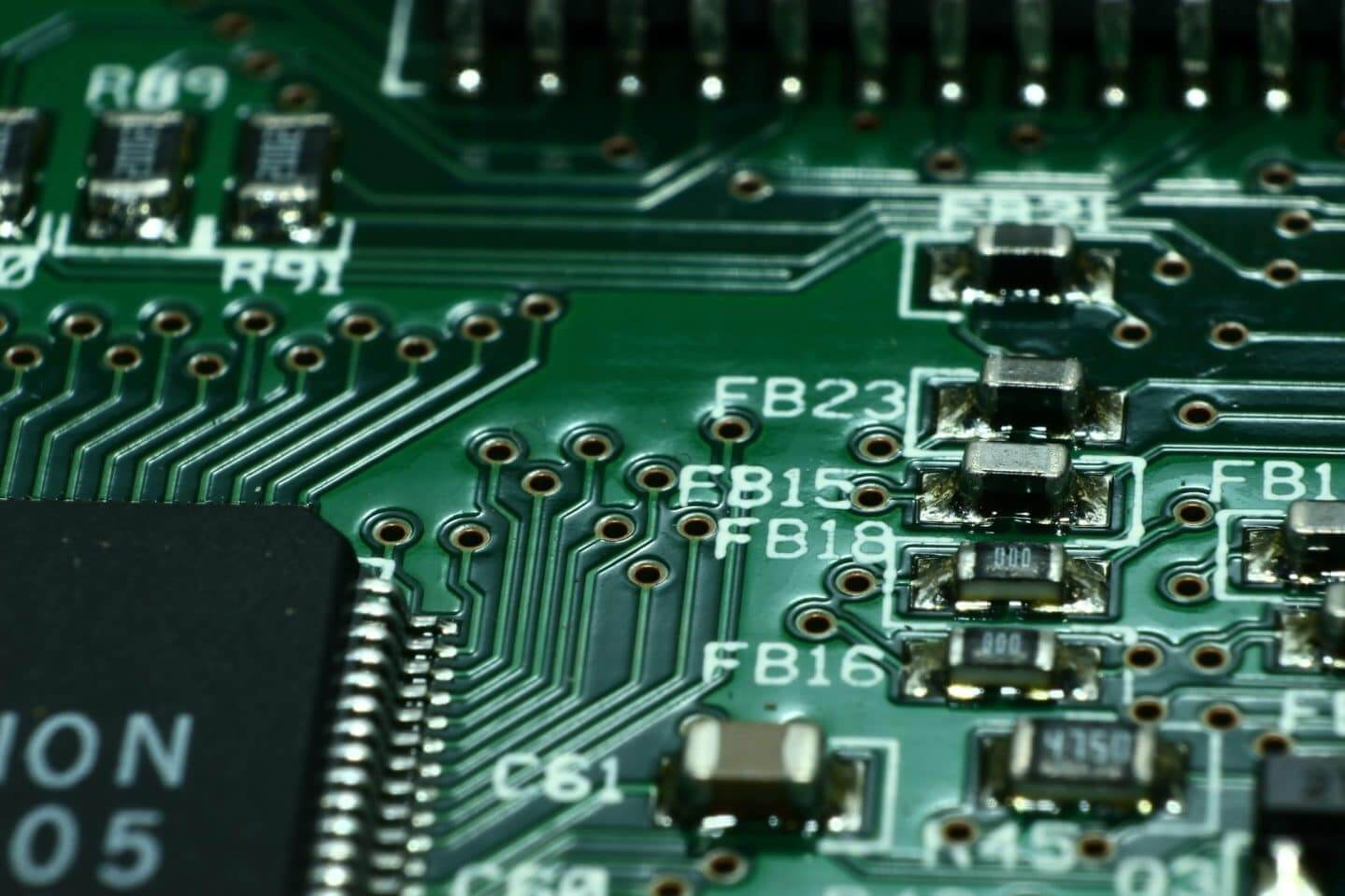

Importance of Cooling Electronics

In order to reduce cost, keep processes running smoothly & prolonging their lifespan, it is of the utmost importance to cool electronics used in industrial applications. The overheating of industrial electronics can cause severe damage to the apparatus & reduce its effectiveness.

With every 10°C increase above room temperature the life expectancy of most electronics is halved. Heat can be generated in an industrial enclosure from a number of sources such as:

- Starter kits

- Servo drives

- Programmable logic controllers

- Inverters

- Variable-frequency drives

- Indicator lights

- Transformers

- Power supplies

Furthermore, heat can be generated from sources which are outside of the industrial enclosure:

- High ambient temperature

- Blast furnace

- Solar heat gain

- Welding processes

- Foundry Equipment

Closed Loop Cooling

Closed Loop Cooling is a method of cooling electrical components whilst the industrial enclosure is sealed. This can be achieved through the use of an air conditioner which can remove heat from inside of the electronics enclosure. For applications which require a temperature to be maintained at or below ambient level it is important to make use of air conditioning units. The cooling duty provided by the air conditioning units should match or exceed the heat produced by the electrical system.

Closed-loop cooling should be used for electronic applications which fall under the following categories:

- Equipment which generates a high heat load from its internal components.

- Equipment which operates in high temperatures most typically over 35°C

- Equipment used in harsh environments such as water treatment plants.