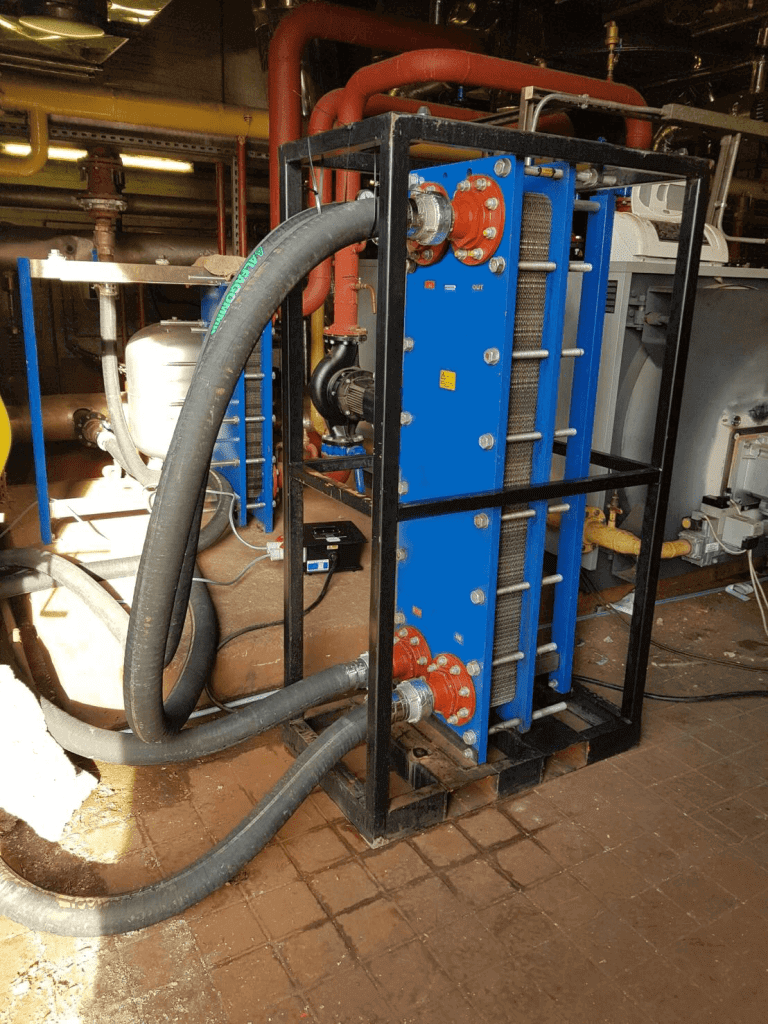

Heat exchanger failure can be incredibly costly for your business with it leading to shutdowns. This blog post will offer a number of tips to help your business clean its heat exchanger, thus saving you money & improving its performance.

Keep a Schedule

It is important to keep a cleaning routine for the maintenance of the heat exchanger. This will help prevent the buildup of sediment to reach levels which could damage the plant & possibly lead to shutdown. To ensure equipment meets regulatory standards & is fully operational, make sure to combine cleaning with inspection routines.

Ultra High Pressure Jetting

The best way to clean the heat exchanger is to make use of ultra high pressure jetting due to its effectiveness at removing scale & deposits from the system. Using solely water is also a more environmentally friendly way of cleaning. Making use of water removes the need of having to dispose of hazardous solvents & detergents.

When cleaning the heat exchanger it is important to make sure all sediment is removed until only the bare metal is visible. This will extend the lifespan of the heat exchanger by keeping the surface to a new factory standard & also its efficiency.

Keeping the insides of the pipework polished will help remove blemishes & therefore improve the liquid throughput.

External Surfaces

Make sure the shell sides, tube bundles & interior pipework are cleaned due to the likelihood of these surfaces building up sediment & chemical deposits. Cleaning the heat exchanger’s outer surface makes it easier for visual inspections to be carried out.

Precision Tools

Removing polymer deposit can be incredibly difficult to remove, however, extra care should be taken when removing it with general tools such as chisels & hammers damaging the heat exchanger itself. Therefore, make sure to make use of band-saws & ultra-high pressure water jetting.