What is a Plate Heat Exchanger?

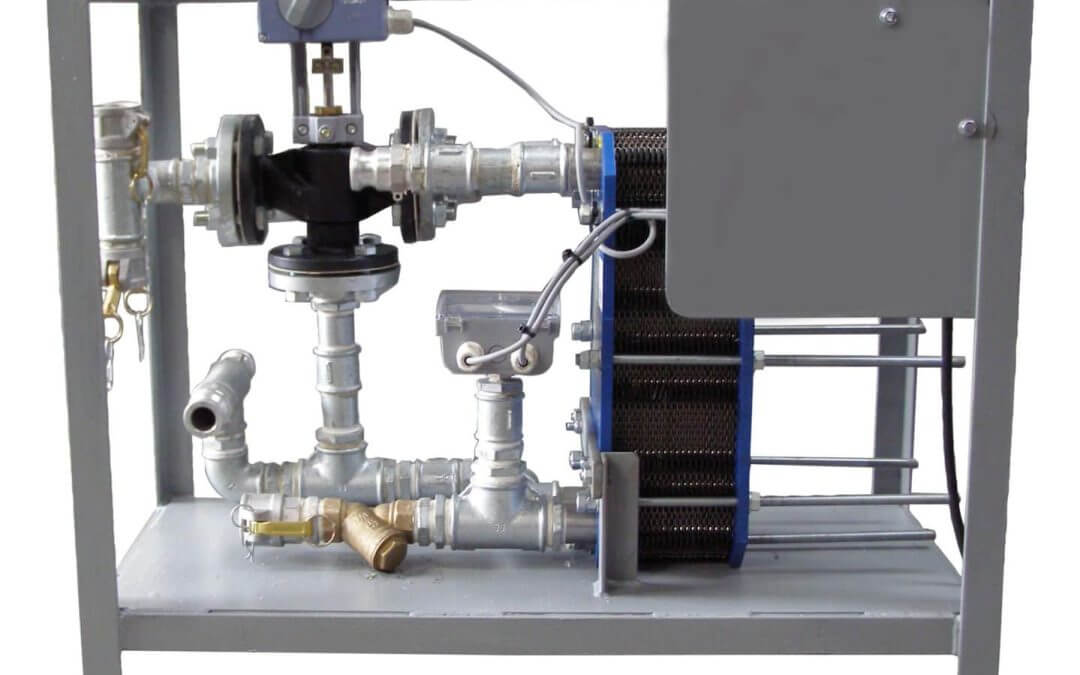

A plate heat exchanger is used to transfer heat energy from one fluid to another. These fluids never encounter each other due to being separated by the heat exchanger. Typically, a plate heat exchanger will consist of several parallel plates positioned above each other, thus creating a passage in which the fluid can flow between. The spacing between two opposite plates provides a channel for the fluid to flow through.

Each plate has an inlet & outlet hole at either end. This ensures that hot & cold fluids pass through alternating channels in the plate heat exchanger. Therefore, one side of the heat exchanger will always contain a hot fluid while the other side contains a cold fluid.

Types of Plate Heat Exchangers

- Brazed Plate Heat Exchangers – These are used largely for refrigeration & industrial applications. The main benefit of brazed plate heat exchangers is that they are highly resistant to corrosion. This is due to them being made from a combination of stainless steel & a copper brazing. Another advantage of brazed plate heat exchangers is that they are inexpensive due to their compact size & efficiency.

- Gasketed Plate Heat Exchangers – These heat exchangers are suitable for a number of industries such as HVAC, Food, Brewing & Pharmaceutical. The heat exchangers make use of gaskets which seal the plates together in the process preventing leaks. Reduced maintenance costs are involved due to the plate easily being removed for replacement and cleaning purposes.

- Welded Plate Heat Exchangers – These heat exchangers are mainly used in the oil, gas & chemical industries. An advantage of these heat exchangers is that they are highly durable and ideal for transferring corrosive fluids or fluids which reach high temperatures. The only issues of these plate heat exchangers is their cost which is accentuated by the fact that the plates are welded together. This means that replacing the plates is difficult & that cleaning the plates is also an issue unlike the removable plates in a gasketed plate heat exchanger.

- Semi-Welded Plate Heat Exchangers – This variety of plate heat exchanger combines the use of welded and gasketed plates. The heat exchanger contains twin sets of plates which have been welded together. These have then been gasketed to other sets, thus making one of the fluid passages welded & another gasketed. The main benefit of a semi-welded plate heat exchanger is that high temperature, corrodible fluids can be transferred on one side while the other side allows for easy servicing.

Materials used for Plate Heat Exchangers and their various uses

- Stainless Steel – Used for drinking water as well as the food & pharmaceutical industry

- Titanium – Used when dealing with salt water & in fisheries

- Non-Ferrous – Used in MRI Scanners & for Laser Cooling

- Carbon – Used when dealing with chemicals